The Challenge

MRO procurement runs on two tracks: planned maintenance with predictable lead times, and emergency breakdowns where every hour of downtime costs thousands.

For planned purchases, buyers must source from a mix of OEM parts, authorized distributors, and aftermarket alternatives—each with different pricing and lead times.

For emergencies, there's no time for the usual back-and-forth. You need quotes from multiple suppliers immediately, and you need to compare them fast.

Add to this the long tail of parts—bearings, seals, motors, filters—from dozens of manufacturers and hundreds of suppliers, and procurement becomes a full-time juggling act.

Common Pain Points

| Emergency breakdowns | 24-48 hour deadlines when equipment fails |

| Long-tail parts | Thousands of SKUs across dozens of suppliers |

| OEM vs aftermarket | Must compare pricing and specs across options |

| Cross-reference complexity | Same part, different manufacturer part numbers |

| Plant manager pressure | "Where's my part?" calls throughout the day |

| Supplier responsiveness | Some suppliers take days to quote |

Common Purchases

How Buyer24 Helps

Urgent RFQ mode

Parallel outreach to multiple suppliers for emergency needs

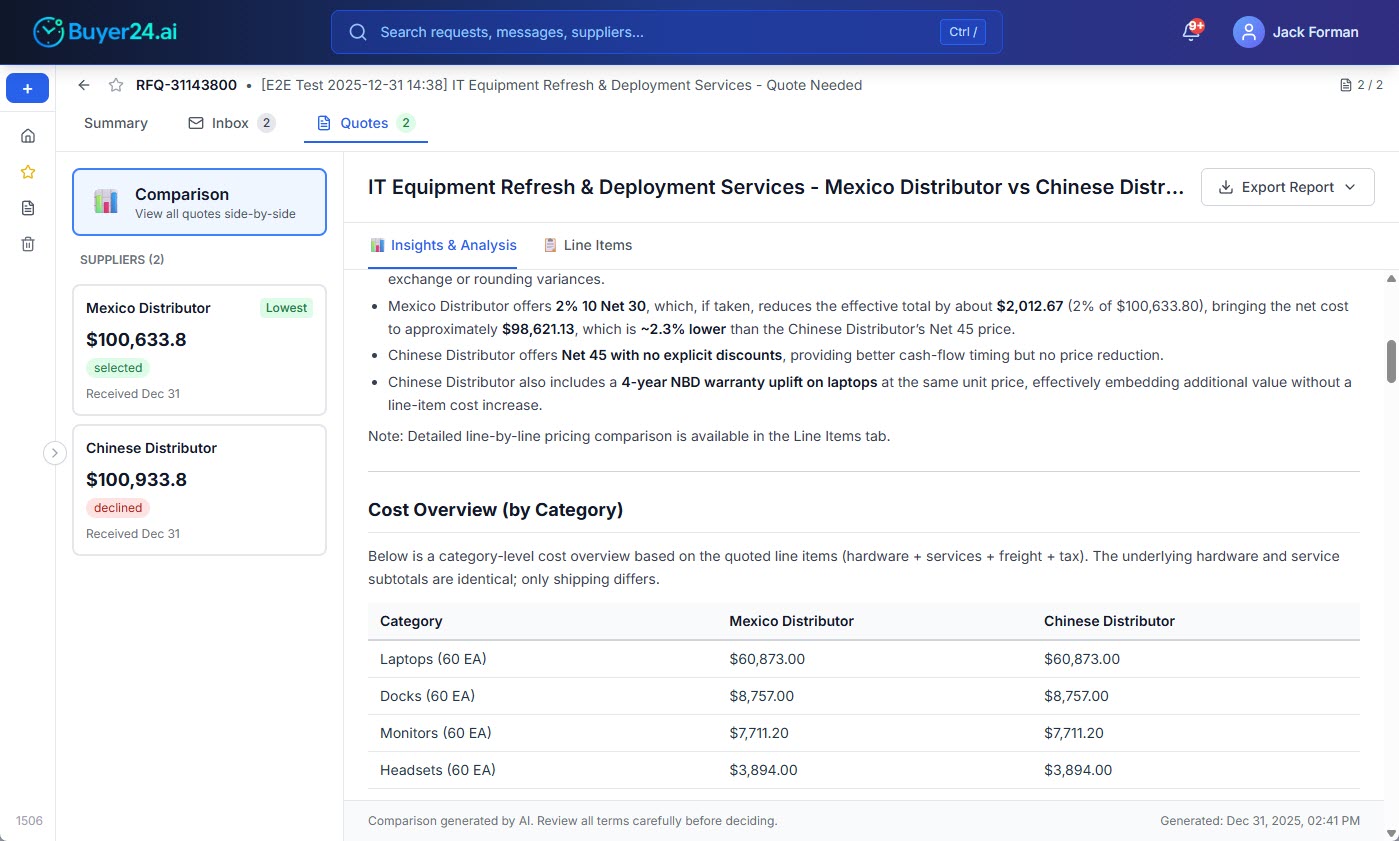

OEM vs aftermarket comparison

See pricing side-by-side with specs

Cross-reference support

AI recognizes equivalent part numbers

Supplier response tracking

Know who's quoting and who's slow

Deadline alerts

Never miss a critical delivery window

"When a conveyor motor failed at 6 AM, I had quotes from four suppliers by 10 AM. Before Buyer24, that would have taken two days of phone calls. We got the plant running again by end of shift."

Procurement Specialist

Industrial Distributor, Midwest