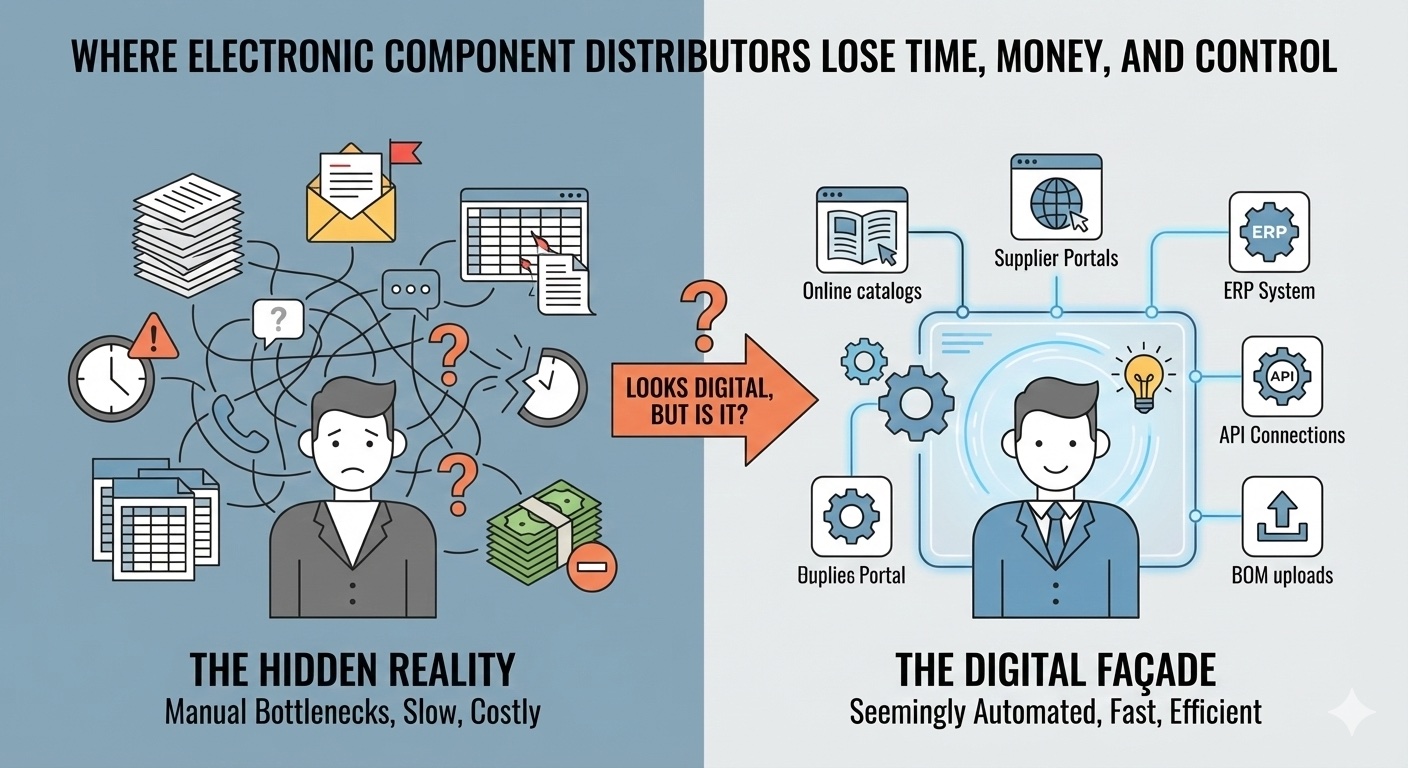

Electronic component distribution looks digital on the surface. Online catalogs, supplier portals, ERP systems, APIs, and BOM uploads give the impression that procurement is highly automated and efficient.

However, when we look closely at how RFQs turn into purchase orders, a very different picture emerges.

Across distributors of electronic components, the same operational bottlenecks repeat themselves. They slow down response times, increase operational costs, and reduce predictability — even in organizations that have already invested heavily in technology.

RFQs Are Digital, But Not Usable

Most RFQs arrive in a structured digital format: spreadsheets, BOM exports, or system-generated lists. Yet very few of them are ready for automated processing.

Typical issues include:

- Incomplete or outdated manufacturer part numbers (MPNs)

- Missing lifecycle or obsolescence data

- Unclear compliance requirements (RoHS, REACH, conflict minerals)

- Absence of an approved vendor list or preferred supplier hierarchy

- Inconsistent formatting across different customers and systems

Because of this, RFQs immediately require human interpretation. Sales engineers, inside sales teams, and buyers must manually clarify requirements, cross-reference part numbers, and contact suppliers for availability.

This turns what should be a fast digital workflow into a slow, manual one. RFQ response times stretch from hours to days, quote accuracy drops due to interpretation errors, and conversion rates suffer as customers move on to faster competitors.

The Gap Between Quote and Purchase Order

Once a customer accepts a quote, many teams assume the hardest part is over. In reality, this is where the most fragile part of the process begins.

Between quote acceptance and PO creation, several things must happen:

- Availability must be rechecked — stock levels change constantly, and what was available during quoting may be gone

- Data is re-entered into ERP systems — often manually, introducing transcription errors

- Commercial conditions must be confirmed — MOQ (minimum order quantity), NCNR (non-cancellable, non-returnable), and allocation rules need verification

- Internal approvals are required — margin reviews, credit checks, and compliance sign-offs add wait time

This creates a manual handoff between sales and procurement, usually handled by order management or inside sales. During this stage, delays accumulate. Orders are frequently lost due to stock changes, pricing shifts, or simply slow internal processing while the customer finds an alternative source.

Supplier Confirmation Still Depends on Humans

Even today, real supplier confirmation is rarely fully automated.

Catalogs and ERPs may display availability and lead times, but this data is often indicative rather than firm. Final confirmation typically comes through email exchanges or manual supplier portal interactions. Suppliers protect their allocation, especially for constrained parts, and buyers must wait for human approval on the supplier side.

The reality:

- Displayed stock may be allocated to other customers

- Lead times shown are estimates, not commitments

- Pricing can change between inquiry and order placement

- Suppliers require manual confirmation for large or unusual orders

While this back-and-forth happens, orders remain on hold and customer commitments become uncertain. This directly impacts supplier response times, delivery promise accuracy, and overall customer satisfaction.

Alternates and Compliance Do Not Scale

In electronic components, substitutions are risky. Unlike commodities where alternatives are interchangeable, every electronic component alternate must be carefully validated.

Validation requirements include:

- Form — physical dimensions, pin configuration, package type

- Fit — mounting compatibility, thermal characteristics

- Function — electrical specifications, performance parameters

- Lifecycle risk — is the alternate also approaching end-of-life?

- Compliance — customer-specific requirements for automotive, medical, aerospace, or military applications

This validation work cannot be easily automated and relies heavily on experienced sales engineers. As RFQ volumes grow, these specialized teams become overloaded. The result is a growing cost-to-serve and slower response times precisely when customers need fast answers.

Many distributors find themselves in a difficult position: they can quote quickly with unvalidated alternates (risking returns and customer dissatisfaction) or quote slowly with proper validation (risking lost sales to faster competitors).

Small PO Errors Cause Large Disruptions

A single mistake in a purchase order can force the entire process to restart.

Common errors include:

- Incorrect MPN or part number transcription

- Wrong packaging type (tape and reel vs. tubes vs. trays)

- MOQ mismatches between customer order and supplier requirement

- Incorrect date codes or revision levels

- Missing compliance documentation

Each correction requires cancellation, re-approval, and often re-quoting. This adds delay and frustration for both internal teams and customers. Suppliers may charge restocking fees or refuse returns on NCNR orders.

Over time, these errors compound. Rework rates increase, cancellation rates rise, and customer trust erodes. What appears as a minor administrative issue becomes a significant drain on profitability and customer relationships.

Lack of End-to-End Visibility

Perhaps the most damaging issue is the lack of clear visibility across the full RFQ-to-PO lifecycle.

Managers often cannot answer basic questions:

- Where are delays originating — in initial response, supplier confirmation, or order processing?

- Which team members or roles create bottlenecks?

- Which suppliers consistently cause delays or errors?

- What is the true cost-to-serve for different customer segments?

- How do response times correlate with win rates?

Without this visibility, organizations rely on manual follow-ups and firefighting instead of structured improvement. Problems are addressed reactively rather than prevented proactively.

This reduces SLA performance, makes outcomes unpredictable, and diffuses accountability. Teams know something is wrong but cannot pinpoint exactly what or where.

Why Electronic Distribution Is Different

The bottlenecks described above exist in many distribution segments. However, electronic component distribution faces unique pressures that amplify their impact:

Supply volatility — allocation constraints, long lead times, and sudden shortages are common. A delay of hours can mean the difference between securing stock and losing the order.

Technical complexity — parts are not interchangeable. Every substitution requires engineering judgment, and mistakes have serious consequences for end products.

Low error tolerance — electronic components go into products where failures are costly or dangerous. Quality and compliance requirements are stringent.

Global supply chains — suppliers and customers span multiple time zones and languages, adding communication friction to every transaction.

Thin margins — distribution margins are tight, making operational efficiency essential for profitability.

This combination of complexity, volatility, and margin pressure means that operational inefficiencies hit electronic component distributors harder than many other industries.

The Path Forward

The bottlenecks in electronic component distribution are not inevitable. They emerge from manual handoffs, fragmented systems, and processes designed for a simpler era.

Organizations that address these challenges focus on:

- Reducing manual data handling at every stage of the RFQ-to-PO process

- Improving data quality at the point of entry rather than correcting errors downstream

- Creating visibility across the full lifecycle to enable measurement and improvement

- Automating routine decisions while preserving human judgment for complex cases

The technology to solve these problems exists today. The question is whether organizations will prioritize fixing their operational foundations or continue to lose time, money, and control to avoidable inefficiencies.